Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

This standard describes the most common embodiment of laboratory accelerometer calibration. Utilizing either a back-to-back (piggyback) reference standard or a specially constructed reference standard accelerometer imbedded inside a precision calibration exciter, this method provides the speed and simplicity of direct sensor under test (SUT) mounting and calibration. Modern computer controlled calibration systems can provide calibrations and prints of calibration certificates in just a few minutes.

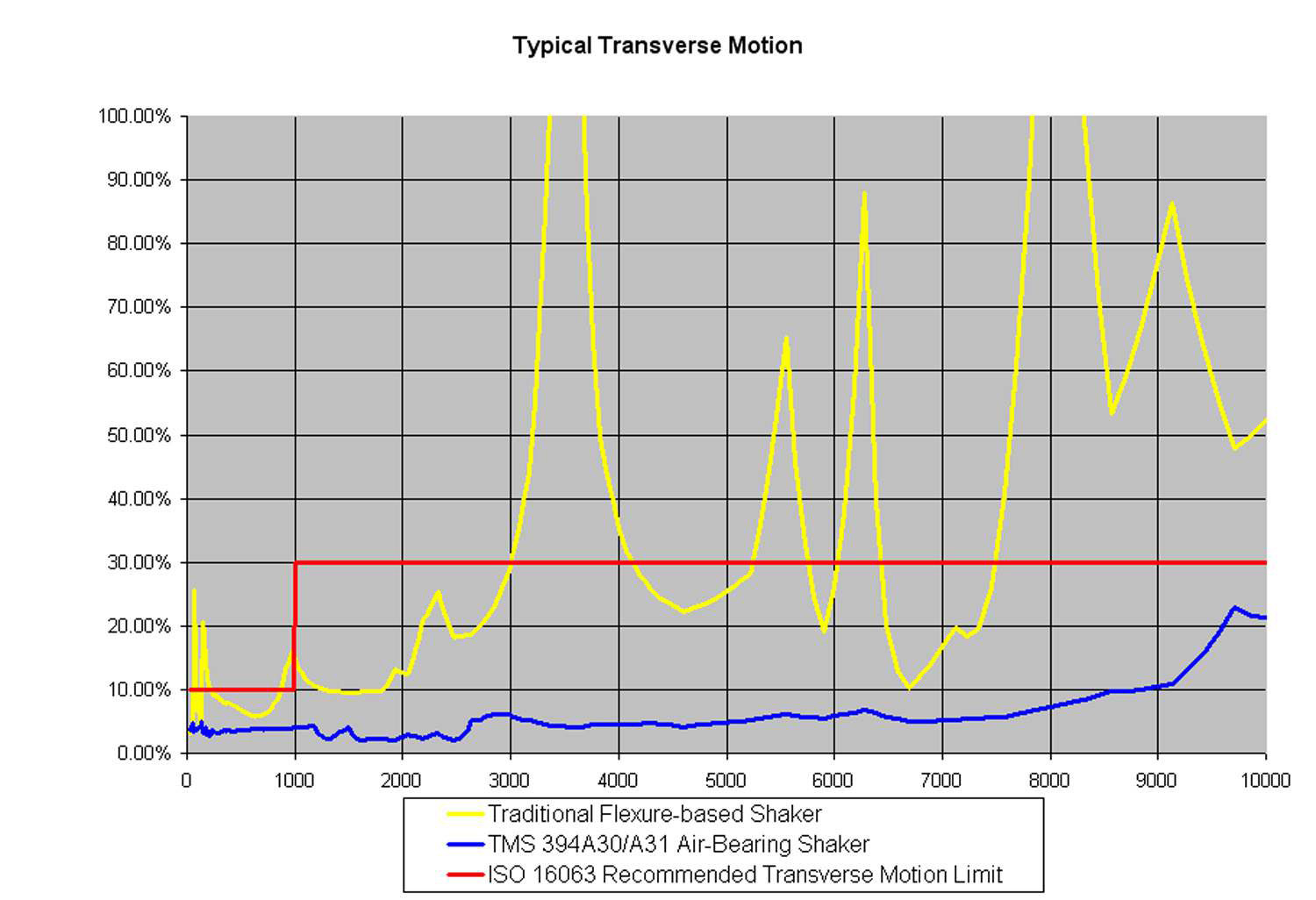

The currently released standard (as of 2003) calls out a typical frequency range of 10 Hz to 10 kHz. Over this range, the exciter should be carefully screened to ensure that the lateral or transverse motion of the exciter does not exceed certain limits. For the range of 10 Hz to 1 kHz, the transverse should not exceed 10% and between 1 kHz and 10 kHz, the transverse should not exceed 30%. Remembering that exciters are structures just like your test articles will remind us that everything has resonances. Virtually all flexure based exciters have modes of vibration in the lateral direction which cause the shaker to exceed these limits for a high quality calibration exciter. A precision class of air bearing calibration exciter exists solely for the purpose of calibration. Recent developments in air bearing calibration exciters have also eliminated some of the longtime usability challenges such as elastic (rubber band) suspensions for the transducer static weight and automatically locking armatures for sensor install/removal without damaging the precision armature/air bearing fit. There has also been significant advances in practical considerations like mounting, electrical isolation, size and reliability.

An additional section to the latest release of the standard takes the method of data acquisition and signal analysis into consideration. If using the mostly abandoned, traditional method of RMS volt meters for input measurement, the system uncertainty must take into account any harmonic distortion cause by the shaker or amplifiers. For this reason, modern accelerometers are based on either FFT or DFT operation on precision Dynamic Signal Analyzers (DSA). Frequency based analysis ensures that extraneous effects like both harmonic distortion and background noise are minimized in their effect on the calibration and uncertainty. An additional benefit of the move to FFT based calibration has been a significant improvement in the speed of calibration where as the actual acquisition portion of a calibration test may take less time than actually mounting and connecting the sensor.

Accelerometer Calibration Workstation with Air-Bearing Shaker

Remembering the discussion from last month, uncertainties are extremely important to understand in the acceleration calibration process. The uncertainties stack up across both measurement components and from reference to primary in link to a traceability (to National Lab or Laser Primary). Accordingly, the uncertainty of a typical accelerometer calibration system falls into three primary areas: the measurement electronics (typically low uncertainty), the transfer standard accelerometer (typically a large part of the uncertainty) and the exciter performance (typically a middle contributor to uncertainty). To achieve the lowest uncertainty, the reference standard should be calibrated in a primary method via laser which adds approximately (0.3% uncertainty). As an alternative, the reference standard can be calibrated against a manufacturers “gold standard” which is traceable directly to a primary and will add approximately (0.8%) uncertainty. Lastly, and most common, the reference standard can be traceable to a manufacturers “working standard” which links through the “gold standard” back to the primary and this method adds about 1.3% to the uncertainty.

Considering all of the above, a birds-eye view of various calibration system implementations goes as follows:

Good – small laboratory exciter, signal generator, back-to-back reference standard accelerometer and a pair of DVM's. This provides the opportunity for simple, manual operation as long as harmonic distortion and transverse motion are characterized, understood and incorporated in the uncertainty calculations (typically around 3-4%). There will be certain ranges to avoid due to high transverse motion however.

Better – A flexure shaker, a back to back reference standard or imbedded transfer standard calibrated to a manufacturer gold standard, a modern PC based DSA card w/ source and 2 channel input for FFT calculation, control software to automate. This provides for reasonable accuracy (typically around 2 – 3% uncertainty) and increased speed/simplicity. Consideration still needs to be paid to frequency regions where the flexure based calibration exciter may have unacceptably high transverse motion.

Best – The basis of a precision accelerometer calibration system starts with a high quality air bearing exciter with specialty designed internal reference standard accelerometer. This type of exciter also allows for additional features such as a mounted resonance health check and basic linearity screening. A precision DSA card can supply both output signal and 2 channels of input measurement with extremely high accuracy, provision for self calibration, and support for automation via any number of convenient languages. The application and control software should also have integrated data basing functions for calibration data storage and retrieval, as well as modular construction to allow the system to expand as user needs grow (ex. shock calibration, low frequency calibration, etc.) Finally, by requesting a laser primary calibration of the systems reference standard accelerometer, the system uncertainty can be as low as 0.6% which is state of the art for comparison calibration.

While this has just scratched the surface of the standard, we are happy to answer any additional questions you might have about the standard or the procedures required to bring your operation in conformance with and the standards you may be eyeing for certified calibrations... we’re here to help, just give us a call!