Main Menu

- Home

- Product Finder

- Calibration Systems

- Calibration Services

- Digital Sensing

- Industrial Vibration Calibration

- Modal and Vibration Testing

- Non-Destructive Testing

- Sound & Vibration Rental Program

- Learn

- About Us

- Contact Us

By far, the most popular configuration of piezoelectric accelerometers for large/multichannel users is the integral triaxial accelerometer. The implementation of a single 4 pin sensor signal connector allows for a common ground and overall 3

to 1 reduction in cabling. While on the surface this may seem trivial, consider that many typical users are now using hundreds of channels for standard vibration tests in the automotive and aerospace industries. This is also relevant

to the consumer appliance/durables market space where sound and vibration quality has moved to the forefront of marketability and customer preferences.

By far, the most popular configuration of piezoelectric accelerometers for large/multichannel users is the integral triaxial accelerometer. The implementation of a single 4 pin sensor signal connector allows for a common ground and overall 3

to 1 reduction in cabling. While on the surface this may seem trivial, consider that many typical users are now using hundreds of channels for standard vibration tests in the automotive and aerospace industries. This is also relevant

to the consumer appliance/durables market space where sound and vibration quality has moved to the forefront of marketability and customer preferences.

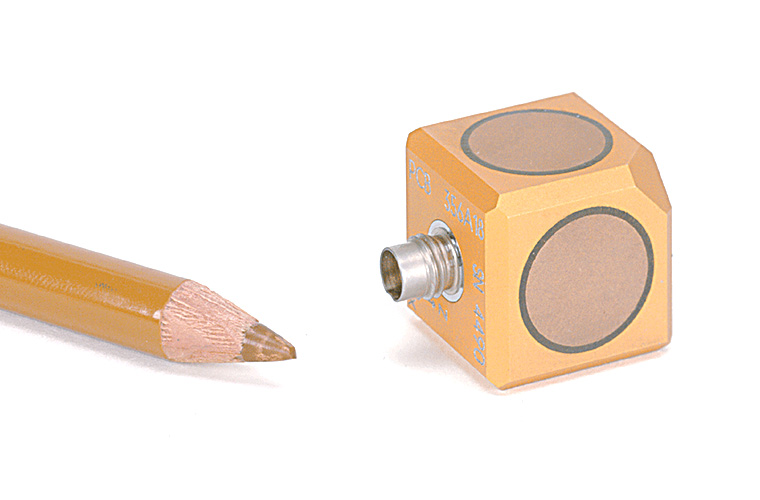

In addition to the reduction in cabling, the integral cubic triaxial package provides practical and versatile mounting to any of five available surfaces (note: the sixth surface fields the output connector). This allows for convenient transducer

mounting and cable routing regardless of required location or orientation. However, it is important to remember to be careful when mounting the triax on its surface with a welded “lid” to the sensor element. Bonding directly

to the lid can reduce the useable frequency response of that axis of the triax by more than 20-30% as compared to bonding on the stiffer corners of the sensor cube.

Part of the road to de facto standardization of triaxial packages

has also been the continual drive toward smaller, lighter and more robust designs. Where older, larger designs may have utilized aluminum housings to reduce weight, the smaller size of today’s triaxes allow users to choose the ruggedness/survivability

of titanium housings and still have light weight sensors. At the extremes, there are 0.25 inch (6.35 mm) triaxial accelerometers (with built-in ICP® electronics!) with 5 mV/g sensitivities weighing only a single gram. On the other end of

the sensitivity spectrum there are seismic grade triaxial units only 0.8 inch (20.3 mm) cube, weighing a total 25 grams yet they have 50 micro g resolution. (Note: for single digit micro g resolution, it is still advised to mount three of the larger

type (3 x 50 gram) single axis seismic accelerometers on a mounting cube if the size and weight can be tolerated.)

In the cost to benefit tradeoff, the most common triaxial accelerometers are now 10 gram, 0.55 inch (14.0 mm) cubes with standard sensitivities of 10 or a 100 mV/g providing resolutions of a few hundred micro g’s. Housed in titanium and value priced, these accelerometers are economical, long-life, general purpose work-horses for the large channel vibration test market. Covering an approximate frequency range of 1 Hz to 5 kHz, up to 50 or 500 g’s, it is easy to see why these models are the most common choices today. If you haven’t looked lately, ask your local application engineer to show you the variety of new ICP® triaxial accelerometers available today.